Lathes / Milling Machines

Drilling、Threading、Knurling、Stamping、Keyway

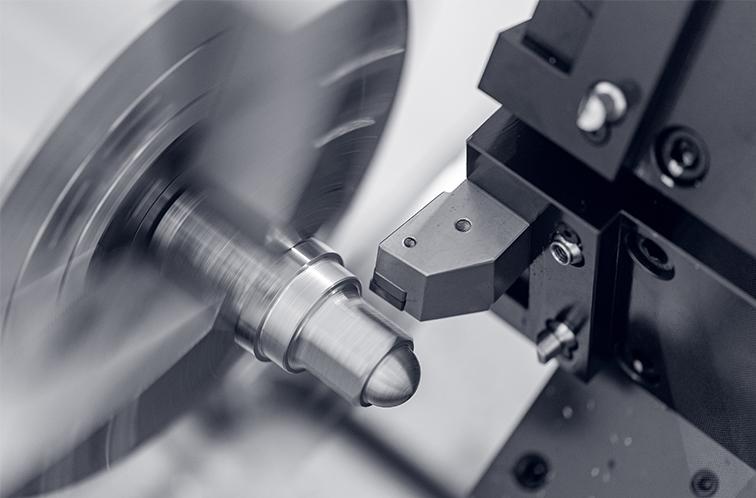

Lathes: A lathe is a machine tool used for metalworking, typically for machining rotating workpieces. By securing the workpiece to the spindle, tools move along the length or circumference of the workpiece to remove excess material. This technique is suitable for producing cylindrical parts, conical parts, and other complex shapes. The advantages of lathes lie in their high efficiency and repeatability, making them an ideal choice for mass production.

Milling Machines: A milling machine is another primarily used tool for cutting flat surfaces, grooves, profiles, and irregular shapes. It employs rotating cutters that move along the workpiece, allowing for various angles and shapes to be machined. Milling machines can operate in either vertical or horizontal positions and are highly effective in producing gears, gear racks, and complex parts.

Hobbing / Shaping

Precision Hobbing、Hard Hobbing

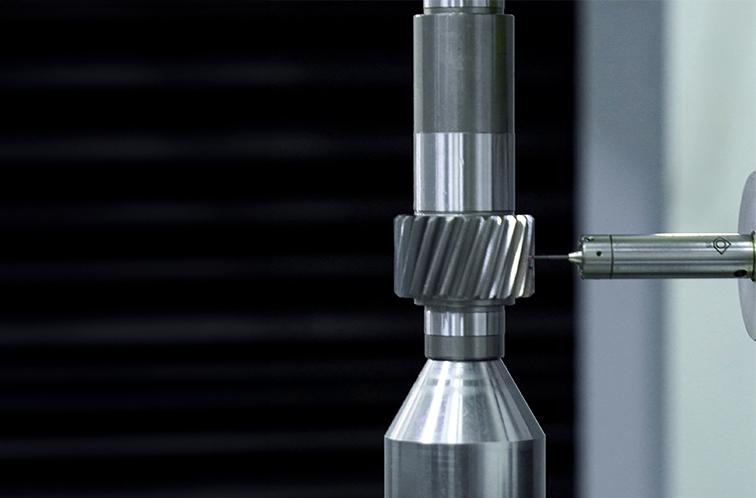

Hobbing: This is a specialized machining technique used for manufacturing gears. A hobbing machine uses a cutting tool known as a hob to cut the tooth profile into the gear. This technique is well-suited for producing large quantities of standard-sized gears and excels in consistency of cutting speed and tooth shape, making hobbing a mainstream method in gear production.

Shaping: This method is commonly used for manufacturing gears with internal grooves or specific tooth profiles. A shaping machine employs specially shaped tools (such as shaper cutters) to perform cutting on the workpiece. Shaping can not only create specific tooth profiles on gears but is also capable of machining various types of workpieces.

Broaching

Keyway、Bolt Hole

Grinding

Gear Grinding、Inner Hole Grinding、Surface Grinding、Outer Diameter Grinding

Grinding is a high-precision metalworking method commonly used to enhance the surface finish and dimensional accuracy of workpieces. During the grinding process, abrasive materials come into contact with the surface of the workpiece under pressure to remove material and achieve the desired smoothness and precision. Grinding can be classified into several types, including:

Surface Grinding: Used for surface treatment of flat materials to ensure plane flatness.

Outer Diameter Grinding: Used for processing the outer circumference of circular workpieces to enhance the accuracy of the outer diameter.

Gear Grinding: Specifically used for grinding the external tooth profile of gears, ensuring smooth engagement and noise control during operation.

Inner Hole Grinding:

Focuses on improving the dimensional accuracy and smoothness of internal holes, suitable for components that require precise fitting.

Wire EDM

Keyway、Bolt Hole

Wire EDM (Electrical Discharge Machining)

Wire EDM is a machining method that uses electrical discharge machining (EDM) technology to cut metal. Through the passage of electrical current through a very thin metal wire (the electrode wire), which moves up and down at high frequencies, the workpiece is continuously eroded until the desired shape is formed. This method is particularly suitable for cutting complex-shaped and thick metal workpieces, ensuring high-precision cutting edges. Wire EDM technology is commonly applied in mold manufacturing, electronic components, and the processing of various high-strength materials.

Finished Product Inspection

Appearance, Dimensions、Tooth Profile, Tooth Shape、Gear Accuracy