Machine Tools

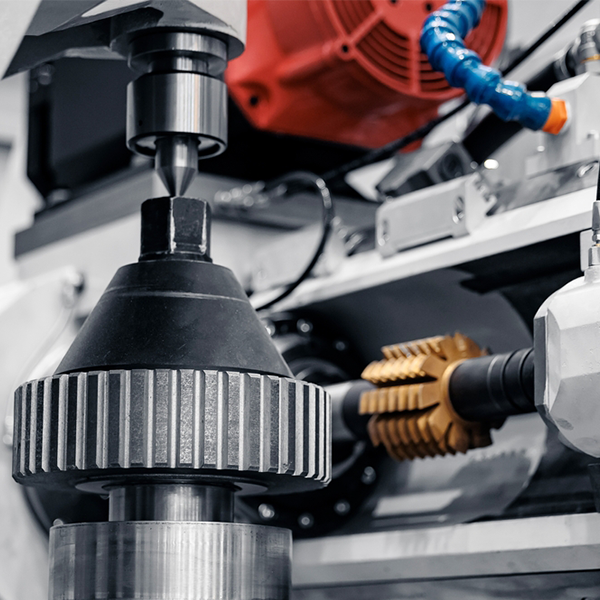

Machine tools are indispensable in modern manufacturing, and gears play a crucial role in their operation.

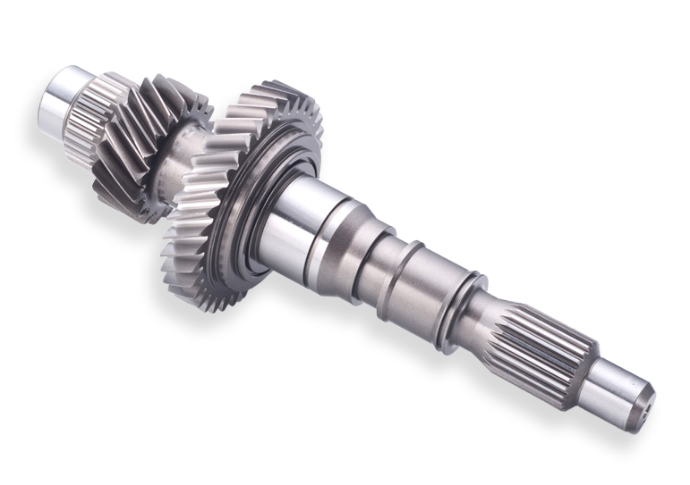

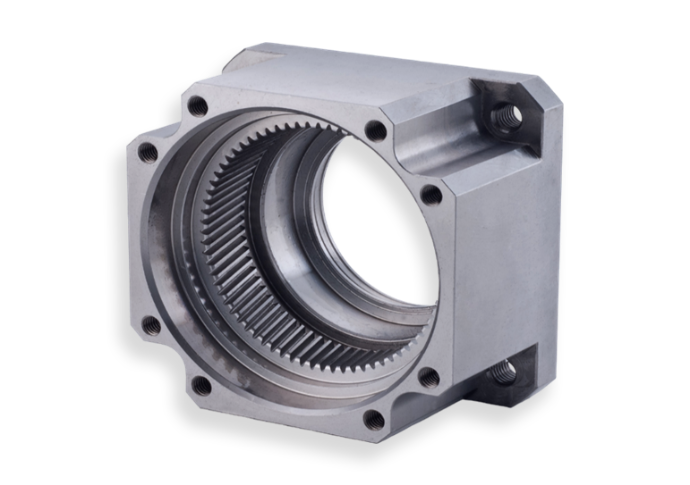

The primary function of gears in machine tools is to transmit power and control motion, ensuring stability and precision during machining processes. In various machine tools such as lathes, milling machines, and grinding machines, gear systems are used to adjust spindle speeds and feed rates to meet the requirements of different materials and machining tasks.

Precision machining imposes high demands on gear design and manufacturing. Typically, gears are made of high-strength alloy steel and undergo heat treatment to enhance wear resistance and fatigue strength. Additionally, the geometric design of gears influences machining accuracy, with well-designed gear profiles effectively reducing vibration and noise during operation, thereby improving machining quality.

With the development of CNC (Computer Numerical Control) technology, many machine tools have become automated, and gear control systems are increasingly intelligent, capable of real-time adjustments based on machining needs. These advancements not only enhance production efficiency but also expand the application scope of machine tools to meet more complex machining requirements.