Reducers

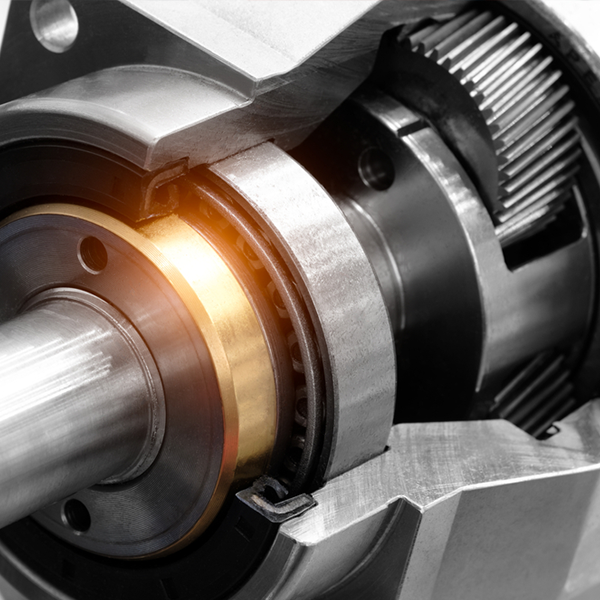

Reducers are devices used to convert high-speed rotation into low-speed, high-torque output, with gears playing a central role. They are widely utilized in cranes, conveyor belts, power tools, and various industrial machinery.

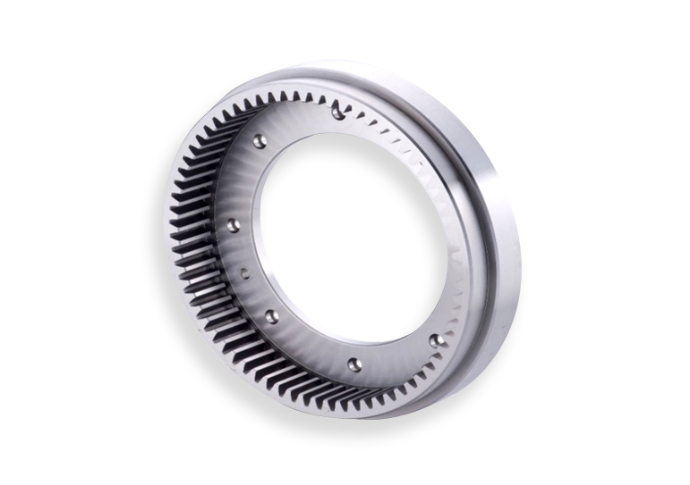

Reducers are typically designed with multiple stages of gears to achieve the desired reduction ratio. These gears can be spur gears, helical gears, or planetary gears, each offering specific advantages for various applications. For instance, planetary gear systems are compact and efficient, making them suitable for small reducers in confined spaces.

The primary function of a reducer is to decrease speed while increasing torque, which is crucial for machines requiring high torque, such as electric cranes and industrial equipment. Through precise gear alignment and the use of high-strength materials, reducers can operate stably under heavy loads and maintain extended service life.

The efficiency of a reducer directly impacts the energy consumption of the entire system. High-quality reducers minimize energy loss, enhancing overall operational efficiency, a critical factor in the current focus on energy conservation and emission reduction. With advancements in technology, digital control has further improved reducer performance, enabling precise speed and torque adjustments and enhancing automation levels. These features make reducers increasingly vital in modern industrial applications.