Automation Industry

Gears are extensively applied in the automation industry, serving as core components for mechanical motion and power transmission. They are particularly important in robots, conveyor systems, and production line equipment.

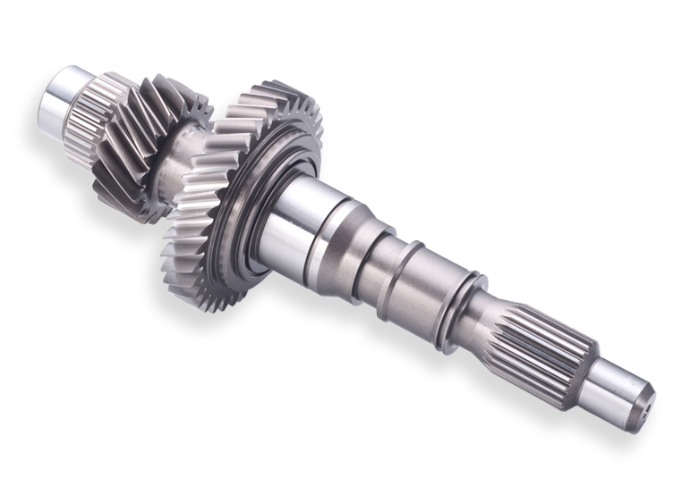

On automated production lines, gears drive various devices for precise movements, such as controlling the rotation, movement, and gripping actions of robotic arms. High-precision and high-performance gear structures are essential for enhancing the stability and productivity of automated equipment. In conveyor systems, gear reducers precisely regulate conveyor speed, ensuring materials reach designated locations at the correct time.

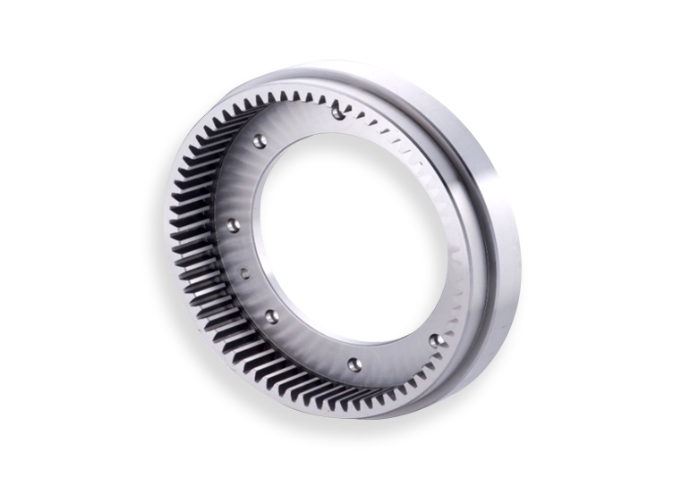

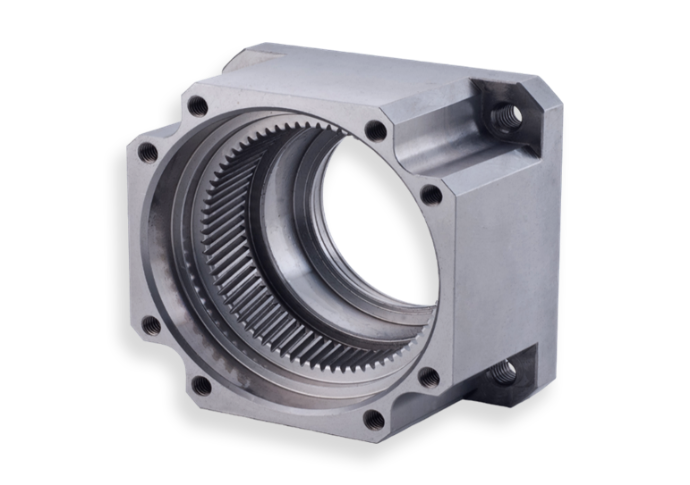

Planetary gear mechanisms are often used in compact applications such as small robots and servo drives due to their compact structure, high load capacity, and efficiency. In automation applications, gears must also prioritize low noise and high wear resistance to meet the demands of long-term, high-frequency operation.

With the adoption of smart manufacturing, gears combined with sensors and control software form intelligent gear systems. These systems enable automatic monitoring and fault prediction, significantly improving the reliability and maintenance efficiency of automated systems.